Introduction: The Hangzhou Summit of the Group of Twenty is the most important home diplomacy of our country this year, and it is also the highest-level and most influential multilateral summit hosted by China since the founding of New China. On August 25, at the tenth day of the 2016 Hangzhou G20 Summit countdown, the China Science and Technology Exchange Center participated in the "G20 National Innovation Competitiveness Development Report (2015 ~ 2016)" press conference and the G20 Hangzhou Summit Preview Released in Beijing. Huang Book pointed out that innovation-driven manufacturing transformation and upgrading is not a return to and repair of traditional manufacturing, but a radical change in the industry, giving birth to new industrial sectors, and establishing a new industrial system and industrial development model. The Yellow Paper specifically opened a "Special Analysis Report", focusing on the in-depth analysis of G20 industrial technology innovation and manufacturing transformation and upgrading. The report believes that the deep integration of innovation and manufacturing will not only trigger a new revolution in the global manufacturing industry, but also become a new focus of international competition and become the dominant force of national competitiveness and international influence. The report believes that G20 countries must further implement strategic innovation to accelerate the transformation and upgrading of manufacturing.

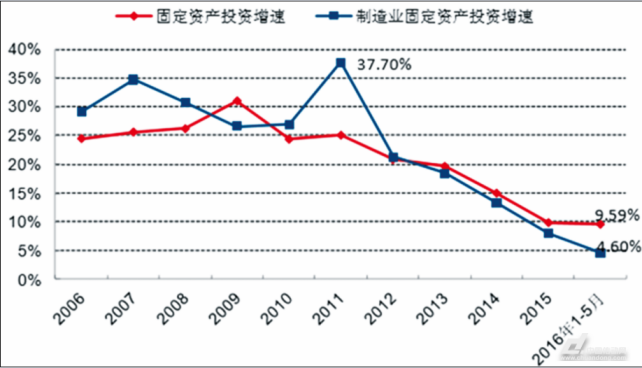

In the new round of industrial layout of the global manufacturing industry, China is still an important engine for driving the world economy forward. From the perspective of the growth rate of investment in manufacturing fixed assets from 2006 to 2016, it has been falling for 4 consecutive years since 2011. Among them, the growth rate of purchase of equipment related to machinery products has also fallen simultaneously. In 2016, the cumulative investment in fixed assets in domestic manufacturing increased. Speed continued to decline, the cumulative year-on-year growth rate from January to May was only 4.6%. It can be seen that although the growth rate of fixed asset investment in China's manufacturing industry has entered the single digit era, high-tech manufacturing industries supported by national industrial policies will continue to be the key driving force for industrial economic growth, supporting China's industrial optimization and upgrading.

Compared with the world's advanced level, China's manufacturing industry is still large but not strong. The gaps in independent innovation capabilities, resource utilization efficiency, industrial structure level, informatization degree, and quality benefits are obvious. difficult. How can traditional industries seize opportunities for transformation and upgrading? In 2015, the State Council issued the "Made in China 2025" strategic plan for comprehensive deployment to advance the implementation of the manufacturing power strategy. The proposal of "Made in China 2025" is essentially a planning guide to promote the transformation and upgrading of China's manufacturing industry, and it is to point out the development direction of Chinese manufacturing industry in the new economic normal.

Manufacturing transformation direction

The general idea of "Made in China 2025" is to adhere to the road of new industrialization with Chinese characteristics, with the theme of promoting manufacturing innovation and development, focusing on improving quality and efficiency, and focusing on accelerating the integration of next-generation information technology and manufacturing to promote intelligence. Manufacturing is the main offensive direction, in order to meet the economic and social development and national defense needs for major technical equipment as the goal, strengthen industrial basic capabilities, improve the level of comprehensive integration, improve the multi-level talent system, promote industrial transformation and upgrading, and realize the transformation of the manufacturing industry from "big" "Strong" historic leap.

Main line: Next-generation information technology and manufacturing integration

Since the establishment of the Ministry of Industry and Information Technology, it has been committed to promoting the integration of the two industries. Through the integration and penetration of information technology, it has had a significant impact on traditional manufacturing. With the advent of a new round of industrial revolution, the role of next-generation information technologies such as cloud computing, big data, and the Internet of Things in the future manufacturing industry will become increasingly important. This is why "Made in China 2025" will accelerate the integration of next-generation information technology and manufacturing as the main line.

Main attack direction: intelligent manufacturing

"Made in China 2025" takes intelligent manufacturing as the main attack direction and promotes the intelligentization of the manufacturing process. Pilot the construction of intelligent factories and digital workshops in key areas, accelerate the application of technologies and equipment such as human-machine intelligent interaction, industrial robots, intelligent logistics management, and additive manufacturing in the production process, and promote simulation and optimization of manufacturing processes, digital control, Real-time monitoring and adaptive control of status information. Accelerate the promotion and application of product life-cycle management, customer relationship management, and supply chain management systems, promote the integration of key links such as group management and control, design and manufacturing, production, supply and marketing, business and financial linkage, and achieve intelligent management and control.

Essence: From resource-driven to information-driven

With the development of next-generation information technologies such as mobile Internet and cloud computing and big data, more and more powerful and intelligent devices on the factory floor have wirelessly connected to the Internet or devices. From this, the Internet of Things and the Internet of Service have been derived, driving the integration of the physical world and the information world in a CPS manner. It can also be said that CPS will enable the manufacturing field to realize the interconnection of resources, information, goods, equipment and people, forming a smart manufacturing environment.

Through interconnection and interconnection, cloud computing, big data and other new-generation information technologies are combined with previous informatization and automation technologies. The production equipment and equipment in the factory are vertically integrated between workers and equipment to connect the entire factory. Together, it forms a CPS, which can cooperate with each other and respond remotely. The production mode has changed from resource-driven to information-driven. The information-driven product manufacturing process reflects the value of intelligent manufacturing, that is, it can scientifically orchestrate production processes, improve productivity, achieve personalized custom production, and can also adjust resource use and use the most energy-saving methods.

Four Ideas of Manufacturing Transformation and Upgrade

Manufacturing industry is a pillar industry for the development of the national economy, and it is also a key battlefield for promoting supply-side structural reform under the current new normal. At present, the development of China's manufacturing industry is facing new situations and new challenges, and there is an urgent need for transformation and upgrading. "Made in China 2025" represents China's top-level design and path selection in the process of transitioning from a manufacturing power to a manufacturing power. It clearly puts forward the "four comprehensive" strategic layout requirements and strives to build China into a manufacturing power that leads the development of the world's manufacturing industry. To lay a solid foundation for the realization of the Chinese dream of the great rejuvenation of the Chinese nation. In the current and future period, to promote the transformation and development of the manufacturing industry, in addition to adhering to the general direction of "Made in China 2025", we will reshape the manufacturing industry from innovative ideas, coordination ideas, green ideas, flexible customization ideas, and other developments in the future. China will also play an important role in the transformation and upgrading of the manufacturing industry.

Creating New Momentum in Manufacturing Industry with Innovative Ideas

Innovation is the primary driving force for the development of manufacturing industry. At present, we should adhere to the concept of innovative development, expand new supply of manufacturing development, and create new momentum for manufacturing development. The first is to implement an innovation-driven strategy to accelerate the development of strategic emerging industries. Strengthen innovation research and development in emerging areas, promote the industrialization of innovative results, and strive to cultivate and develop a number of strategic emerging industries such as high-end equipment manufacturing, new materials, new energy vehicles, energy-saving and environmental protection equipment, and biomedicine, and improve the manufacturing industry supply system. The second is to promote collaborative innovation across industries and industries, and promote the development of intelligent manufacturing. At present, the global manufacturing industry is deeply integrated with the new generation of information technology. It is necessary to increase the integration of industrialization and informatization, and actively develop intelligent equipment such as high-end CNC machine tools, industrial robots, and intelligent transformation of traditional mechanical equipment to promote the intelligentization of manufacturing, Network and information development. The third is to strengthen the basic innovation capacity building of the manufacturing industry. The focus is to break through the bottlenecks that have restricted industry development in the fields of core basic parts, advanced basic technology, key basic materials, and industrial technology foundation for a long time, clearly identify the key breakthrough directions, and enhance the overall development momentum of the manufacturing industry. The fourth is to improve the manufacturing technology innovation system. It is necessary to build a sustainable technological innovation system with the enterprise as the main body and the market as the guide. At the same time, it must strengthen the combination of industry, university, research, and research to form a joint force of technological innovation in the whole society, and strive to break through a batch of key commonalities with global influence and strong driving force technology.

Promote the optimization of manufacturing structure with the concept of coordination

First, accelerate the "de-capacity" and transformation of traditional manufacturing industries, and optimize the industrial structure of manufacturing industries. At present, through comprehensive means such as mergers and reorganizations, elimination of backwardness, and strict control of new production capacity, the excess capacity of manufacturing industries such as steel and cement should be actively resolved; meanwhile, traditional manufacturing enterprises should be encouraged to carry out technological transformation and upgrading in key areas, and actively build traditional manufacturing industries. An industrial structure that develops in harmony with emerging industries. Second, strengthen the coordinated development of manufacturing regions and optimize the industrial distribution system. The regional development of China's manufacturing industry is uneven, but there is ample room for industrial development and room for manoeuvre. At present, in combination with regional development strategies, we should actively support the central and western regions to undertake the industrial transfer of the manufacturing industry in the eastern region, and give play to the resource advantages and development potential of the central and western regions. , Optimize the resource allocation of manufacturing in the eastern, central and western regions. At the same time, it is necessary to promote the coordinated development of large, medium and small enterprises and improve the manufacturing industry organization system. While giving play to the leading role of the pillars of large state-owned enterprises, it is necessary to actively encourage private enterprises to become larger and stronger, and increase support for SMEs in terms of industry access, tax incentives, technical services and financing support.

Promote Sustainable Development of Manufacturing Industry with Green Concept

First, actively develop green manufacturing and increase manufacturing energy conservation and emission reduction. At present, we should focus on promoting the green transformation of “two high” industries such as iron and steel, nonferrous metals, chemicals, building materials, textiles, printing and dyeing, etc., strengthen the application and monitoring of energy-saving and environmentally-friendly process equipment in key industries, eliminate backward production capacity with high pollution and high energy consumption, and promote key industries The energy consumption per unit of industrial added value, material consumption and pollutant emissions reached advanced levels. Secondly, strengthen the research and application of green products and increase the supply of green products. On the one hand, we must vigorously develop environmental protection equipment, research and promote green process equipment such as desulfurization, denitrification and dust removal, and heavy metal pollution reduction; on the other hand, we must vigorously develop new energy-saving terminal equipment to reduce the energy consumption and emissions of manufacturing end products. Third, improve the comprehensive utilization efficiency of manufacturing resources. Actively promote the industrial scale development of resource recycling, improve the recycling of waste water or waste heat resources in heavy industry, vigorously develop the remanufacturing industry in the fields of automobiles, construction machinery, and actively promote the low-carbon, recycling, and intensive development of the manufacturing industry.

Promote the transformation of manufacturing industry with the concept of flexible customization

Customized production is a new capability for enterprises in the Internet era, a logical starting point for Industry 4.0 and intelligent manufacturing, and a major opportunity for industrial change. Customized production mode is the process of "enabling" information technology to equipment, products, people, and processes, and it is a process of replacing asset generality with asset specificity. A few days ago, the General Office of the State Council issued the Opinions on Giving Play to the Leading Role of the Brand to Promote the Upgrade of the Supply and Demand Structure, which clearly clarified the main tasks and key projects of giving play to the leading role of the brand. In the supply structure upgrade project, it was mentioned that it is necessary to enrich the variety of products and services, and it is important to support enterprises to use modern information technology to promote personalized customization and meet differentiated needs. "Customized production is a new type of capability for enterprises in the Internet era, a logical starting point for Industry 4.0 and intelligent manufacturing, and a major opportunity for industrial change." An Xiaopeng, deputy director of the Ministry of Industry and Information Technology and Software Services, said that companies are encouraged to develop personality Customized and flexible production, and the important sign of personalized customization is the change of production methods.

The manufacturing sector accounts for 40% of China's GDP and plays a significant role. Cultivating and developing manufacturing is a strategic measure to promote the transformation of development methods and the adjustment of industrial structure. Scientific and technological innovation and the development of emerging industries have fostered new breakthroughs. New breakthroughs in information technology, biotechnology, renewable energy and other new technologies are brewing, and the development of emerging industries worldwide has entered an accelerated period. We hope to see more and more manufacturing companies embark on this path and lead our Chinese manufacturing industry to the top of the world.